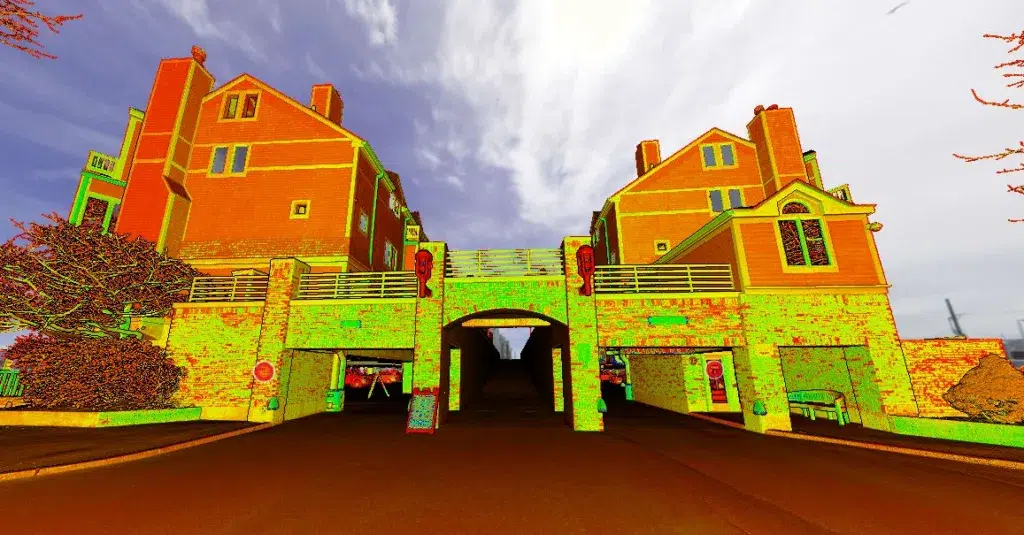

Portsmouth Naval Shipyard Super Flood Basin

At 5,000 tons, this Super Flood Basin was delivered to the Portsmouth Naval Shipyard (PNSY) to support the Navy’s future fleet of submarines and enhance the operational capabilities of one of the nation’s most vital military shipyards.

Location

Kittery, Maine

Sector

Military

Services

- Survey-Geomatics

- Construction Survey

- Quality Assurance & Control

Project overview

This new 5,000-ton Super Flood Basin enables safer, more efficient submarine access to Dry Dock No. 1 at Portsmouth Naval Shipyard. Part of a national modernization effort, it replaces outdated buoyancy-assisted docking with a direct, secure entry solution.

project Details

Survey-geomatics for next‑generation dry dock access

As part of a $21 billion effort to upgrade and modernize the nation’s four public shipyards, each of them more than a century old, the creation of the super flood basin means PNSY can now lift submarines without the use of buoyancy assist tanks allowing for safe, direct entry to the dry dock. Akin to how the Panama Canal works for super tankers, these structures, and supporting expanded waterfront and landside infrastructure, means Virginia-class submarines that could previously only safely access the shipyard’s Dry Dock No.1 with the use of buoyancy assist tanks, an old-fashioned and risky operation, now have an entrance to bring access up to modern standards. This will help enable the 221-year-old Portsmouth Naval Shipyard, the nation’s oldest continuously operated public shipyard, to speed maintenance and repairs.

Sebago Technics played a key role in supporting the construction team with on-site survey geometry control to ensure tight construction tolerances were met and maintained for the success of all the teams involved. A Sebago Survey-Geomatics Team member spent nine months on-site daily at the Cianbro facility, located on the waterfront in Portland, supporting the construction of concrete formwork and maintaining the on-site survey control located directly on the Super Flood structure itself, which was floating on a barge moored at the facility’s dock.

This work played an important role in the project by providing quality control and assurance documentation of the embedded locations and alignments, as well as casting flatness of the concrete to .005’, ensuring the required watertight fit with the Caisson Gate which will nest into it at the completion of the project.

Explore related projects

See how we transform plans into impactful places across the region.